Exceptional Contract & Toll Manufacturing You Deserve

CJB Industries provides a wide range of chemistry services across our three facilities to meet your standards of quality, efficiency and reliability. From custom formulating, milling and blending services to filling, packaging, warehousing and logistics, we deliver the best value in the industry.

We’re equipped to assist a diverse mix of companies – from using our manufacturing and formulation expertise to help small companies overcome production challenges, to supporting the production and expansion strategies of mid-sized companies, to reliably delivering high-quality products for multi-national companies.

Our highly efficient equipment, state-of-the-art labs and well-trained workforce enable us to offer options that meet your project requirements and achieve your business goals. For example:

- Our employees are known for innovative problem solving and work closely with you to design solutions customized to your needs.

- Our facilities are highly adaptive to changing requirements, and we’re able to rapidly expand to accommodate increased demand.

- Daily receiving, shipping and production reporting keeps you informed and ensures we’re meeting expectations.

Our Partner for Formulations Development, Process Optimization and Pilot Plant Services

CJB Applied Technologies is at the forefront of formulations development, process optimization and pilot plant/scale up. We’re committed to working with you throughout the product development cycle – concept, development, formulation, testing, scale-up, and packaging. We specialize in chemical and biological products in the agriculture, specialty and industrial sectors. Our state-of-the-art laboratories include a synthetic chemistry lab and a Biosafety Level II bioconversion lab, and our facility includes an onsite greenhouse to accelerate testing. We hold several certifications, and our labs are continually updated to comply with regulations affecting the pesticide, chemical and other industrial markets.

CHEMICAL MANUFACTURING SERVICES

Liquid Formulation and Processing

Our equipment and technologies allow us to provide you with a wide range of solutions to your quality, formulation and capacity challenges. We handle:

- Multiple stainless steel tanks with agitation on load cells capable of batching from 1,500 to 6,000 gallons

- Stainless steel tanks/reactors jacketed with agitation on load cells for batches from 1,500 to 3,000 gallons

- Polypropylene liquid blending tanks with mixing from 3,000 to 10,000 gallons

- High-speed Cowles shear mixing for 3,000 gallons

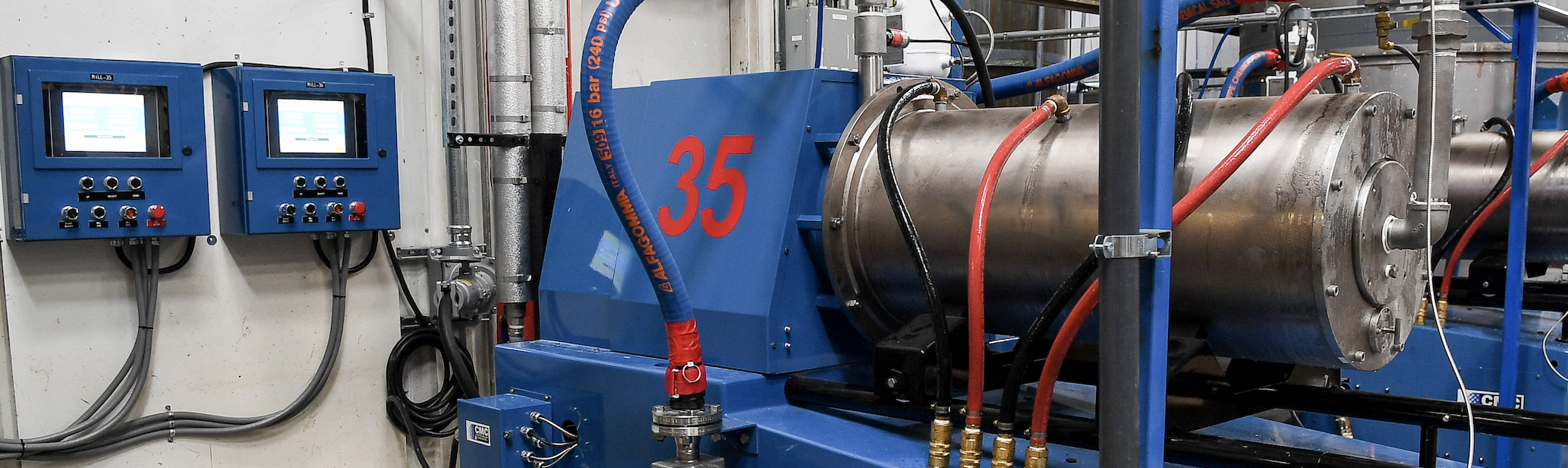

- Multiple media bead mills from 45 to 120 liters

- Carbon steel horizontal mixers for high-viscosity liquid mixing greater than 750,000 centipoise

- Stainless steel and polypropylene bulk storage tanks from 5,000 to 15,000 gallons

- In-line shear mixing and other specialty processing equipment

Solid Formulation and Processing

Our facilities feature multiple solid blending, coating and impregnating technologies so we can handle a wide range of products with precision and efficiency.

- Carbon steel paddle and ribbon blenders

- Stainless steel V-blenders

- Munson mixers for continuous and batch solid mixing and coating/impregnating

- Stainless steel Littleford Plow mixer with heating/cooling jacket

- Coating systems and other specialty solid processing equipment

Chemical Packaging, Repackaging and Filling Services

We’re committed to ensuring you always have the products you need when you need them, whether they’re just several ounces or in bulk. To do so, we provide you with efficient options for packaging, repackaging, liquid and solid filling, and shipping. We maintain flexibility in equipment, volume and staffing so we can rapidly respond to your changing needs. Our equipment includes:

- Single and multi-head liquid filling lines for packaging from 4 ounces to 5 gallons with bottom up capability

- Semi-automatic liquid tote, drum, and pail filling

- Automatic and semi-automatic solids filling of bags, jugs, and pails

- Auger open mouth and valve bag fillers

- Solids filling of totes and drums

- Packaging rework and repackaging

Our multiple production lines are configured to provide:

- Induction sealing

- Labeling

- Ink-jet printing

- Case erecting and sealing

- Palletizing

- Stretch wrapping

- Specialty packaging services

Laboratory Services: Quality Control

Our advanced-degree chemists and state-of-the-art technologies allow us to meet exacting quality control standards, conduct performance properties testing, and support your project initiatives. Each chemical manufacturing site features a Quality Control lab staffed by a PhD chemist and degreed associates who work closely with your quality control and product formulation teams.

- Gas chromatography (GC)

- High pressure liquid chromatography (HPLC)

- Viscosity testing and measurement

- Particle size analysis: Coulter

- Moisture analysis: Karl Fischer titration and Digital Moisture Balance

- Photovolt brightness meter

- Titrations and wet chemistry

Custom Chemical Manufacturing

We have the expertise and commitment to help you meet your unique product and process demands by designing and implementing customized solutions. We’re able to add systems, processes or equipment; design new processes; and implement your processes.

Supply Chain Support

To address the increasingly complex supply chain challenges, we’re committed to helping you increase your supply chain efficiencies. Our services include:

- Transporting product via our rail access and railcar loading capabilities, via three nearby interstates, and via multiple seaports

- Providing value-added warehousing and logistics support

- Designing customized solutions that may include third-party service providers in close proximity to our facilities

- Delivering products directly to automotive and OEM production lines

Capabilities at Our Facilities

Cypress Street Plant

On the site of our original operations, the Cypress Street Plant has expanded tremendously over the years into a world-class contract chemical manufacturing facility that features:

- Site: 5 acres

- Plant: 106,000 square feet under roof

- Packaging: 4 ounces to bulk

- Capabilities: Liquid and solid processing, formulation, bead milling, high viscosity liquid processing, solids milling, screening, granules, suspension concentrate (SC), emulsifiable concentrate (EC), suspo emulsion (SE), microemulsion (ME), complex formulations, blending, packaging, and shipping

- Products: Fungicides, insecticides, biocides, coatings, adhesives, industrial, intermediates, and specialty chemicals

- Lab facilities: Quality control lab

- Transportation: Easy access to interstate highways and seaports

Cypress Street Annex

The Annex provides additional capacity, warehousing, and a formulations and development lab to expand our capabilities in chemical manufacturing, including combustible liquids. The Annex features:

- Site: 5 acres

- Plant: 37,000 square feet under roof

- Packaging: 1 gallon to bulk

- Capabilities: Liquid processing, formulation, SC, EC, blending, packaging, and shipping

- Products: Fungicides, insecticides, biocides, coatings, adhesives, industrial, intermediates, and specialty chemicals

- Lab facilities: Formulation and development lab

- Transportation: Easy access to interstate highways and seaports

Gil Harbin Plant

Acquired in 2009, our Gil Harbin Plant experienced expansion and updates in 2022-23 to add bulk capacity and expand and upgrade warehouse, lab and office facilities. The site features state-of-the-art chemical manufacturing technologies, diverse packaging capabilities and rail access.

- Site: 10.5 acres

- Plant: 213,500 square feet under roof

- Packaging: 4 ounces to railcar load

- Capabilities: Liquid and solid processing, formulation, bead milling, granules, screening, SC, EC, SE, ME, complex formulations, drying, blending, packaging, and shipping

- Products: Herbicides, coatings, adhesives, industrial, intermediates, and specialty chemicals

- Lab facility: Quality control lab

- Transportation: Easy access to interstate highways, rail and seaports

Get Started Today!

1. TELL US ABOUT

YOUR PROJECT

Share information about your project needs in our Contact form. Our experienced team will review your request to prepare questions for further insight into your project.

2. MEET WITH US TO

PROVIDE MORE DETAILS

We’ll explore your goals and objectives, discuss our questions and gather further specifications to see if we’re a good fit for your project.

3. ALLOW US TO CREATE A SOLUTION FOR YOU

Using our expertise in contract manufacturing, we’ll develop a solution that meets your needs.